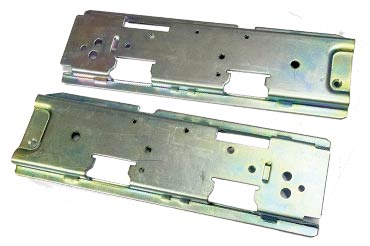

In the bustling world of manufacturing, certain elements stand as unsung heroes, and among them are press tools. Despite their quiet presence, these tools form the backbone of mass production, quietly crafting intricate metal components with unmatched precision and efficiency. Let’s take a closer look into this realm, unveiling the significance and vast applications of these often-overlooked tools.

Understanding Press Tools

Press tools serve as specialized instruments that, when used with presses, mold and shape sheet metal into precise designs. Comprising two key components:

Upper Die: This element exerts pressure on the sheet metal, conforming it to the shape of the lower die.

Lower Die: Featuring a cavity mirroring the intended final part’s design.

The force applied by the press drives the sheet metal into the lower die’s cavity, ultimately producing the desired shape.

The Crucial Role

Press tools hold paramount importance for several reasons:

Mass Production: Enabling the consistent and efficient creation of large volumes of identical parts.

Precision: Crafting parts with unparalleled accuracy and reliability, ensuring uniform quality.

Cost Efficiency: Offering an economically viable solution for producing large quantities compared to alternative methods like machining.

Versatility: Adaptable to fabricate a diverse array of shapes and sizes, catering to various applications.

Diverse Applications

These tools find extensive use across diverse industries for various purposes, including:

Automotive: Crafting chassis components, body panels, and engine parts.

Electronics: Manufacturing casings, heat sinks, and electronic device components.

Appliances: Producing parts for washing machines, refrigerators, and other appliances.

Construction: Crafting metal roofing panels, siding, and building materials.

Variety in Types

Different types of press tools cater to specific functions:

Blanking Tools: Carve out specific shapes from sheet metal.

Piercing Tools: Create holes in the metal sheets.

Forming Tools: Bend and sculpt sheet metal into intricate geometries.

Drawing Tools: Deep draw metal to form cup-shaped parts.

Embossing Tools: Imprint raised or recessed patterns on the metal’s surface.

The Evolving Landscape

The future of press tools looks promising, marked by technological advancements leading to:

Increased Automation: Integration of robotics and automation to enhance efficiency and reduce labor costs.

Improved Materials: Development of stronger, more durable materials enabling the creation of complex parts.

Advanced Design Tools: Leveraging advancements in 3D modelling and simulation software for precise design and optimized tool performance.

In Conclusion

Press tools, the silent champions of manufacturing, hold a pivotal role in shaping the products we interact with daily. Their significance lies in their prowess to facilitate mass production, maintain precision, ensure cost-effectiveness, and adapt to diverse needs. Continual technological strides promise an evolution in press tools, unlocking the potential for crafting even more intricate and innovative products in the years to come.